Your expert partner in CAE simulation

Your expert partner in CAE simulation

Test validation

For us, simulation is neither a competition nor a substitute of testing, but a valuable completion. Both, simulation and trials, contribute to the efficient development of a high-quality product.

For us, simulation is neither a competition nor a substitute of testing, but a valuable completion. Both, simulation and trials, contribute to the efficient development of a high-quality product.

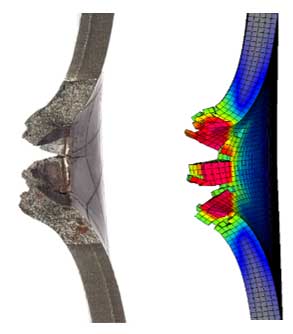

In addition, only the comparison of simulation and tests offers the findings and the increase in know-how that ensure the qualified CAE models and simulations that are needed for an efficient and successful support in future development. Thus, a meaningful simulation always starts with the definition and description of the materials’ properties, ideally basing on extensive specimen and component tests. Furthermore, a matching of simulation and test for a specific loading situation or a defined load case allows for an important increase in quality and validity of a CAE calculation. In addition, simulation enables a targeted planning in the run-up of trials, as it helps to identify a construction’s potential weak points. Due to the animated representation of the process, simulation facilitates the in-depth analysis of a test and thus a purposive constructive design.

Our services in tests and validation:

- Experimental support at research centres and test laboratories

- Matching and comparing evaluation of test and simulation

- Optimization of the simulation models concerning their validity

>>Click here to see videos on the topic.

During the development of a customer’s product, we often get the opportunity to match our simulations to tests. This comparison may lead to an important improvement in validity and predictive power, or it confirms the high level of correlation that has already been achieved. Both possibilities offer a valuable input for further qualified CAE models and simulations.

Simulation enables for a comprehensive examination of the scenario, which is another important aspect as it offers a deeper understanding of cause and effect, of action and reaction during a damage process under diverse loads and diverse boundary conditions. We and our customers benefit from these findings as they often allow a more targeted choice of measure for enhancement and optimisation.

Another advantage of the interaction of test and simulation is the useful input that simulation offers for a specific test setup, as it identifies the product’s relevant area beforehand.

We apply test validation from the very start of the calculations and simulations for a sound and extensive material description for the product being developed. This comprises specimen test under tension, pressure, bending, and shearing enabling for a static and dynamic as well as temperature dependent characterisation. In addition to these specimen tests a need for tests on components and assemblies may arise, for example on screw, brackets, and further small structures.

Kontakt

INPROSIM GmbH

Birkenweg 1

64354 Reinheim

Germany

+49 (0) 61 62 / 65 23

www.inprosim.de

info@inprosim.de

Kontakt

INPROSIM GmbH

Birkenweg 1

64354 Reinheim

Germany

+49 (0) 61 62 / 65 23

www.inprosim.de

info@inprosim.de