Your expert partner in CAE simulation

Your expert partner in CAE simulation

Materials

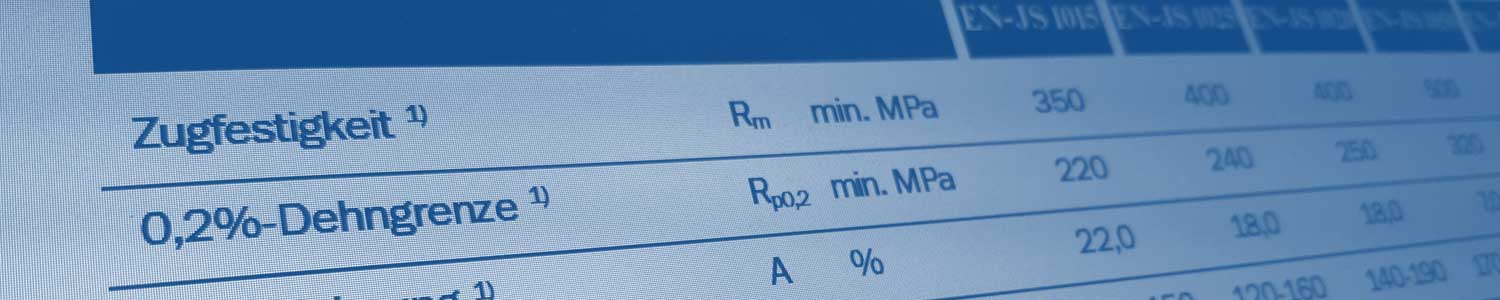

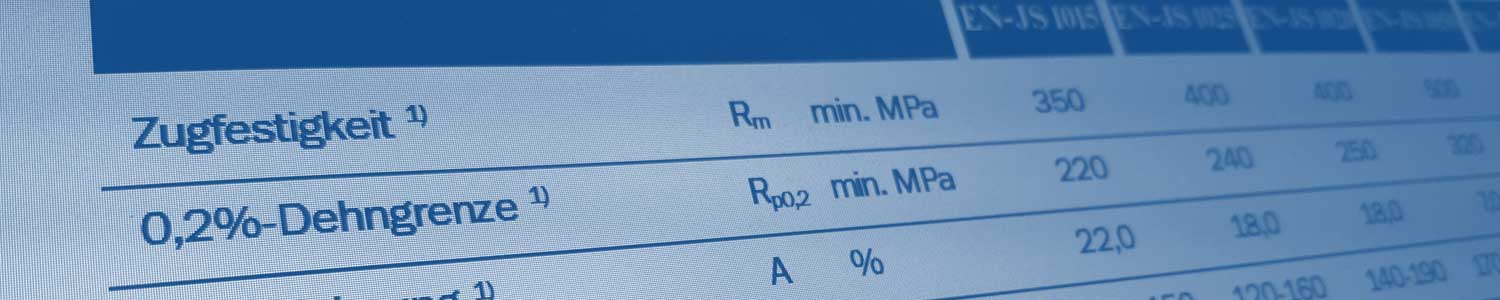

As we offer simulations for such a manifold range of products and components, the range of the diverse materials used is widely varied, too. For all these materials (metals, plastics, or any other material) one rule always applies: an adequate and as in-depth as possible definition of the materials’ properties is the indispensable basis of a successful, meaningful calculation and simulation. Beyond the typical elastic range an elaborated material description comprises the non-linear, plastic deformation behaviour up to failure behaviour at rupture, the latter being crucial especially in explicit simulation. In addition, this non-linear description takes into account further effects such as temperature dependency, strain-rate dependency, dynamic hardening, and triaxiality as well as potential influences of assembly.

As we offer simulations for such a manifold range of products and components, the range of the diverse materials used is widely varied, too. For all these materials (metals, plastics, or any other material) one rule always applies: an adequate and as in-depth as possible definition of the materials’ properties is the indispensable basis of a successful, meaningful calculation and simulation. Beyond the typical elastic range an elaborated material description comprises the non-linear, plastic deformation behaviour up to failure behaviour at rupture, the latter being crucial especially in explicit simulation. In addition, this non-linear description takes into account further effects such as temperature dependency, strain-rate dependency, dynamic hardening, and triaxiality as well as potential influences of assembly.

Our services in the materials area:

- Creation of material cards for explicit crash and containment simulation

- Implementation of material cards into the desired CAE code (LS-Dyna, Abaqus, Radioss, PAM-Crash)

- Application of material definitions appropriate to the load (Johnson-Cook, Gurson and GISSMO with MAT_ADD_EROSION)

- Verification of material definition / comparison of material properties

- Advice in choice of materials appropriate to the load and use

- Optimisation of material usage

>>Click here to see videos on the topic.

As there are nearly no limits to possible application of CAE simulation, an abundance of materials is employed. This reaches from typical steels and ferrous materials to non-ferrous metals such as aluminium, magnesium and titanium; from synthetic materials such as thermoplastics and thermosets to foams, textiles, and fabrics. The choice of materials involves design-engineering matters like the load behaviour under forces, deformations, and temperatures. Besides it comprises issues like production and manufacturability; and, of course, economic efficiency needs to be taken into account at all times.

In CAE simulation a high quality of material definition is of fundamental importance. Thus, a crucial task is the creation of material cards, basing on specimen and component tests, and the verification of these so-called material decks. This material definition needs to describe a material’s linear and non-linear deformation behaviour as well as its damage behaviour with extreme deformations, cracks, and ruptures.

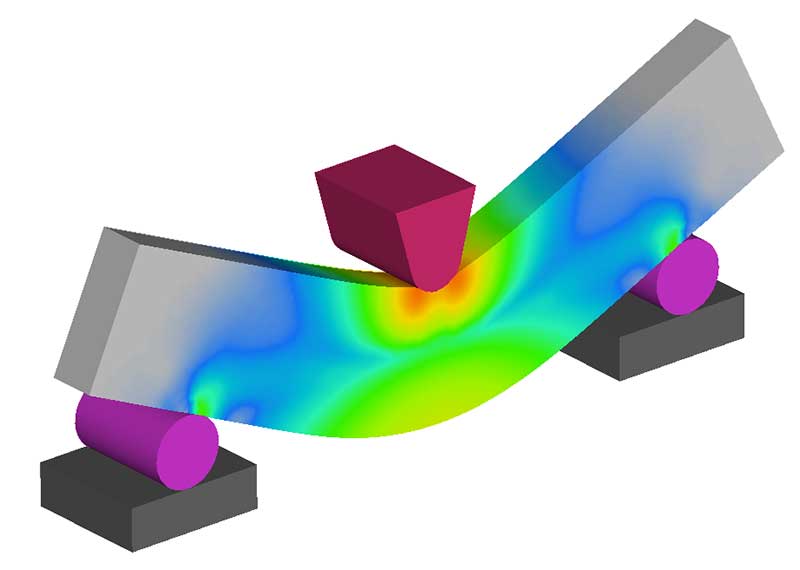

Being able to meet the complex demands of material description requires expertise as well as constant further training. In addition, we participate in various research projects that deal with characterising diverse materials under diverse specifications by numeric approaches and descriptions. One focus is on materials for turbomachines such as forging and casting materials. We have been chairing FVV’s research project FVV0936 “containment safety”, FFV – ‘science for a moving society’ being a research association formerly named Forschungsvereinigung Verbrennungskraftmaschinen. Research topic FVV0936 covers a detailed examination of aluminium and cast-iron materials, reaching from specimen tests under static and dynamic load to the penetration of projectiles at moderate temperatures for compressors as well as at high temperatures for turbines. These investigations were implemented into an appropriate material description for the numeric application in containment simulation.

Kontakt

INPROSIM GmbH

Birkenweg 1

64354 Reinheim

Germany

+49 (0) 61 62 / 65 23

www.inprosim.de

info@inprosim.de

Kontakt

INPROSIM GmbH

Birkenweg 1

64354 Reinheim

Germany

+49 (0) 61 62 / 65 23

www.inprosim.de

info@inprosim.de