Your expert partner in CAE simulation

Your expert partner in CAE simulation

Turbomachines and drives

The area of turbomachines and drives covers all sorts of rotors and machines with rotating components such as turbines, compressors, pumps, turbochargers, and fans. It comprises stationary power plants for energy production and engines in aerospace industry as well as turbochargers in the automotive and in the large engine and generating stations area.

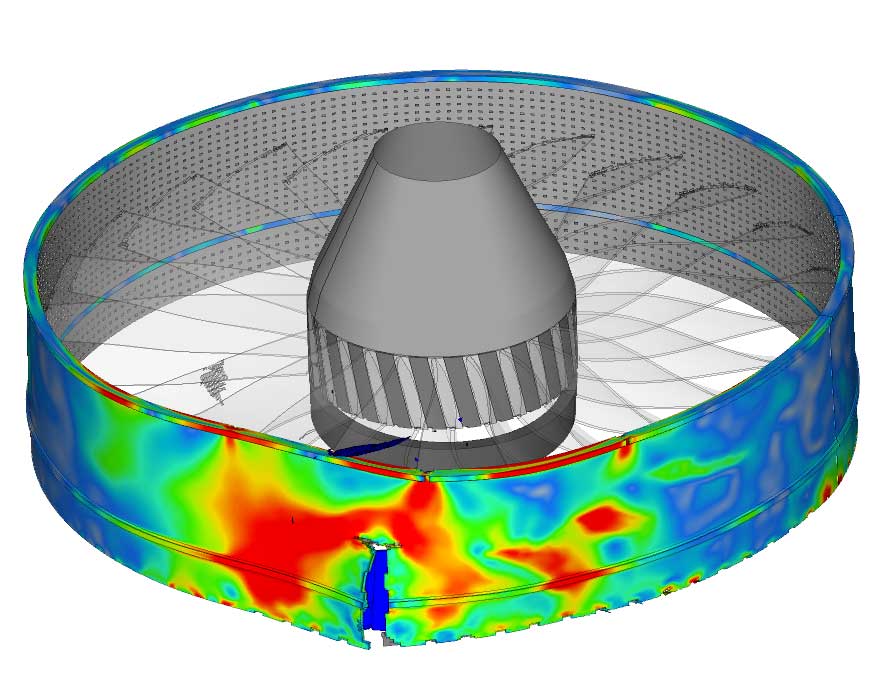

Concerning turbomachines and drives one focus is on containment safety. This containment load case handles with a potential machine damage, in which a rotating part fails and then penetrates its surrounding structures due to its high energy. Thus, it poses a threat to men and goods in the machine’s environment. Containment simulation aims in avoiding such a puncture by targeted design measures. Basing on our proven expertise in containment simulation we have been successfully assisting many globally operating manufacturers of exhaust gas turbochargers for many years. We help them to achieve the requested containment safety of their machines, with a minimum of expensive tests and while development cycles shorten continuously.

Our services in turbomachines and drives:

- Burst of wheels / disks and blade loss in turbomachines

- Investigation of axial as well as radial turbomachines

- Burst test and centrifugal tests of rotors and rotating components

- Hub burst and disk bursts of rotors and wheels

- Rupture of grinding wheels as well as of tappets and disk pumps

- Tear off of integral as well as connected rotor blades

- Fan-blade-off-tests for engines and large fans

- Damage and rupture of motors’ con rods and crank shafts

- Puncture of oil pans, casings, and lids

- Structural stability of centrifugal and protective housings

>>Click here to see videos on the topic.

A containment failure or burst damage occur when a part of a machine’s rotor or further rotating components breaks and its fragments impact onto the surrounding casing structures. As these fragments have a high kinetic energy resulting from the rotation they may deform, damage, or even penetrate the housing, putting nearby people and goods at risk.

The CAE simulation of such a burst scenario allows for a detailed containment analysis and makes it possible to design and optimise the turbomachine’s structures and its casing in such a way as to impede the fragments from puncturing and penetrating to the outside. Thus, containment safety is achieved as the surroundings are protected from the fragments.

Formerly, it was mainly tests that determined a turbomachines technical design and, in particular, the evidence of its containment safety. Today, simulation allows to optimise the construction in terms of containment safety even during the design phase. Furthermore, simulation may actually provide evidence of the containment safety, giving the customer an enormous advantage concerning the development time and costs, all the more as it saves complex and expensive trials.

Many years of experience and the cooperation with many reputable customers as well as our membership in FVV (‘science for a moving society’) provide us with a sound and detailed expert knowledge that we are happy to use for our customers’ benefit. We offer a wide range of simulations in this complex field: for the support during the development phase, for the evaluation of containment tests, for the examination of occurred damages, as well as for the eventual proof of containment safety.

Kontakt

INPROSIM GmbH

Birkenweg 1

64354 Reinheim

Germany

+49 (0) 61 62 / 65 23

www.inprosim.de

info@inprosim.de

Kontakt

INPROSIM GmbH

Birkenweg 1

64354 Reinheim

Germany

+49 (0) 61 62 / 65 23

www.inprosim.de

info@inprosim.de